As a Diamond Setter for the past 21,918 days (and still counting!), I've seen some mediocre attempts at getting some waxes ready for casting. From these questionable and feeble attempts,

After many years of well-proven techniques, I'd like to share my experiences with YOU!

When you apply a wax sprue, there are some necessary techniques. Not everyone will encounter them, but "it's good to know how to work with them, not against them!"

For this essay, I started with 180 photographs, taken over many (3) months, as of now the number is down to 151 Why are there so many? It's because there are times that the wax-creation you just made, will lead to the poor flowing of metal and not reaching the desired areas!

Your sprues could be the main problem! No matter how great your creation is, the basic & simple sprue will be the cause of a potential disaster! You could many spend hours on your bench, then believing you've done well, then at the very last moment, you find that your sprue has not been properly attached (I have many photographs of these particular problems).

I keep saying "OMG, there are mistakes galore here with this mediocre injected wax, but so great for this blog!"

2) That being done, I made this strip of wax wider, by adding a new little plate. This is for other uses!

3) I used a newer wax, as it had it cast with 'shared claws'. The result was "poor" & not to my liking!

In the lower photo, you can see a better form. There are some mediocre results with its sprues.

4) The joining sprues have a lot to be desired, let's examine them "one at a time"!!

The 'joining spots' are not equally made near the shank & near to the top!

5) The pink top is well made and so is the shank, it's the joining sprue that is my main concern!

6) The wax join needs to remade and the joint needs to be filed then allowing the wax to flow easier!

7) To repeat this process, again the "shared-claws" with its joining that is not well joined..:>(

8) The silver top was a good attempt, but after closer examination, it wasn't good. I scrapped it after casting as too much time & labour were needed in the repairing process.

9) This is a near disaster in the joining of the many sprues. Let's start now to explore each of them.

10) The joining on the left doesn't appear to be well-joined. The ring size must be made NOW!

11) The top appears to be not aligned properly, it looks crooked!

12) The residue of dirt must be removed...NOW!

13) The underneath holes are not cleaned and are not made round. A bad habit to learn!

In my estimation, it looks like a disgusting attempt to create something decent. We all learn from our errors, agree? Again, I did this purposely, just for this essay!

14) The top must be filed smoothly and add new wax to repair any surface defects. The two-axis are not made well, both of them need to be curved. The "length and width" curves were missing!

With my 10 power loupe, I saw some flat surfaces and these were not needed!!

15) I would fill in with more wax underneath to allow for greater freedom of the metal to flow easily.

16) You can see that the top is really crooked. I'd remove the top and restart the 'waxing process'. Being too quick at this stage leads to many errors!

17) As shown in the first photograph, I filled in the holes from wanting to use this plate from a Pave to..? (whatever I need later on). I must use my "wax file" to smooth this wax strip..to be shown later!

18) From this angle, I can see just how poor this 'heating of the sprue' is now looking, This is not acceptable. Not enough wax joining the top to the shank, it's crooked and soldered sideways.

19) Not enough wax in the joining! There is only one solution and that is to remove the top to the shank and start again! It will save you time and save you much labour..:>(

20) This is my diamond-setting bench, before making it into a wax-carving bench. I must have a bur inventory of well over 2,000 burs, many of them are not seen here.

You notice because of my improved eyesight 20/15 <=> 20/20, I don't need the use of a microscope.

(20-B) This is my same diamond-setting bench, with much modification, it's now a waxing bench.

21) In this average-looking, rubber mould is a regular ring that will soon be used for casting. There is a definite problem lurking!

22) Already to the "well-versed, wax-removing jeweller", you will already notice where the problem lays. Look right at the bottom of the ring & shank!

23) Don't pull out the warm injected wax. It's warm because of the wax has to be warm so the wax will flow into the cavity of the rubber mould!

24) THIS IS THE PROBLEM. You see two thicknesses of the sprue. I will never accept this for any form of casting. Plus the two sprues are of two separate thicknesses. Totally not acceptable..!!!

25) Good grief! This section must now be removed and re-attached with even sprues.

26) You can see just how the error was made after the two metal sprues were attached before the metal mould.

27) In this different project, I added more sprues everywhere. These were added for wax and then even metal flowing for the casting of the metal.

28) Same as the rings, I squeezed the two ends together and the wax literally 'jumped out'.

29) Now you can see how clean the mould looks, no errors anywhere!

30) I'm now joining the "inside, cross-over piece of wax", only for easier flowing of wax in the mould. There are so many steps to watch out for, in this topic.

If one error is not seen, you might have a very poor result, there will be many 'ripple effects' leading further to poor castings. "THERE ARE NO SHORT-CUTS".

31) I just found a wax form that I used to illustrate why I have so many additional sprues. If I skip one step, then the ring is ruined.

I want, if needed, extra sprues just to make darn sure the wax or metal flows where it is required.

32) These "light-coloured spots" are the filed areas where the additional waxing took place.

33) You will see just where I place my middle finger. I place the wax just here and only for support.

The finger is warm and this soft heat might soften the wax, plus I want full access to any wax working. If I place my wax on my bench pin, I won't have full or complete access.

This is such a delicate process, it can be a bit frustrating, to say the least.

34) To avoid any warm-finger bending, I hold my fingers always on the sprues. Here, I am attempting to fill in the setting holes, this is of no consequence to this topic, but just to show you how I'm now

holding this very fragile wax pattern.

35) Sometimes I feel that there is a need to set more stones into my (favourite) heart pendant. That being the case, I will add more or remove a few holes, I can't do this in metal.

The best way is to do this in wax, it's cheaper and must faster...:>)

36) Here is a little collection of sprues & additional 'feeder lines' for better flowing of wax!

37) This sprue looks good, but in truth, this is a very mediocre joining of sprues. They are not fully joining, or attached.:>(

38) All of my rubber moulds had this extra piece of wax, I didn't realize this until a few castings later.

Always check & re-check your mould, in case of a constant error taking place. As like this, locate the error in your rubber mould and either discard the mould or fix it, if you have the opportunity.

39) I always like to add more sprues, I don't care if I have to cut them off afterwards, at least the metal is flowing better, because of them. This step is so-o important.

40) I'm so happy with this correctly made design. Since this design is small, I didn't need anything further. If the sprue is longer, the hot wax will cool too fast & not reach the tip of this horses head.

41) This wax-form is full of extra residue, it needs to be removed NOW! This is so much easier than in the metal stage.

42) Clean out the setting holes, plus clean out the extra straight lines seen underneath the horses face! Basically, clean everywhere, including "the eyes" of the horse.

I mentioned so many times before, it's far easier to clean now, than after!

With this "wax-cutting" bur, I opened up all and every hole that was full of wax. This bur has only

3-teeth and come in only two sizes. Please be careful, as they are extremely sharp & cut the skin with little effort!

46) Please excuse the "out of sequence" photographs!

Clean the inside of the wax-circle, try and remove all of those 'dirt spots'.

The easiest way is to use your bur, and dig deep and then fill in the hole again. Your wax for the metal casting must always be in pristine condition.

47) Here is a close-up of those dirt spots, these must be removed. While you're at it, add more wax to the sprues.

48) I would remove these ill-placed sprues and attach them again.correctly and in the middle of the project.

49) This is the reason just why the sprues must be centred correctly.

50) I'm not at all satisfied with just one or two sprues. For this important project, I need full access for all of the metal to flow to all areas of the circle.

51)

These are my wax-burs, you will notice the minimum (3) amount of bur-teeth, The reason is that these 'rotating-teeth' won't get plugged up with wax.

52) Now you can see just why extra sprues are needed. "Always have extra, more the merrier!"

53) In this photograph, I just 'flooded' the under-neath 'demo-plate' with extra wax, "I'd rather be safe, than sorry!"

54) I separated all of the claws before casting. If some of the wax-claws are missing, then add wax to the tips...NOW!

55) The 'Pink' added line is added just in case an insufficient amount of metal gets to reach the very important areas.

56) On this wax for "three horses", I added three additional wax-lines, I'll 'feel' safer that way during the casting.

57) I found a better wax-sprue, with a wider base, can you see the difference? Agree?

58) You can see the hot wax at the tip of the wax-pen. Drop it to the base of the sprue, not at it.

59) Here is where the hot wax should be situated. If the pen-tip touches the sprue, heat will destroy the wax, you need it just at this one spot!.

60) This is how much extra wax you need, the sprue is slightly crooked, don't worry about it. We're only concerned with how much will be given to the shank.

The shank looks a bit short of wax, I would add extra along from the middle and further along the shank. It looks too thin on the 'left side'..:>(

61) Here is a great idea for you in applying a new wax sprue. Just split the end with your saw-blade and split it down until you can easily bend the wax. Then touch some wax to the end until it will hold the wax item.

62) Get that new wax area right into your item, as seen! Let the warmth of your fingers mould the split-ends just to hold it.

63) Now you can just flood the whole area with wax!

64) Now you can compare my "additional-waxing" to the original. Which do YOU approve?

65) I always add more wax to the base and the main-line.

66) Here is another example of 'additional waxing'.

67) This is another example of putting more wax-lines to very long & thicker projects. I would have used even more near the front of the horses face!

68) Even when I saw that this wax-soldering was sufficient, I thought that a bit more would be required!

69) The PINK coloured wax is the newer wax that was placed to reinforce the original sprues. As I only have one chance in this casting, I don't want it to be messed up!

70) Always look with a 10 power loupe, as sometimes a sprue may not be solid, as shown here!

71) On a belt-buckle, make sure that the "belt-pin" doesn't touch any of the additional wax-joins!

71) These little 'marked spots' are original injection spots, fill them in NOW! When everything is completed, double & even triple check for any little defects.

This is a very difficult casting, I won't allow for any unforeseen problems, even though this is two-piece casting. Problems might occur!

I want everything clean, it's much easier to 'fix' the problems in the wax, than in the metal.

I suppose I'm too precise, but in this 'game', being precise is the 'route to take'!

72) Although this supplying of sprues were attached by another company, I always check them once they get into my hands. Those folks think of "speed & money, not always wanting to be accurate"..:>(

73) When you are attaching additional settings, please make sure your waxing doesn't get too sloppy!

74) There seems to be a "VEE" shape in this sprue, not always is this a good omen. Get more wax in between the "VEE" and be safer!

75) "Not always the joining of sprues should be in the horizontal stage" Ignore this and just use your imagination and place your sprue anywhere you want.

Just get that sprue to join anywhere that it is comfortable! In this photograph, I used height to 'jump over' and get to the right spot!

76) My main concern is to have the wax & metal flow from point "A" to point "B" successfully! I decided to change the number of sprues.

79) Sometimes I prefer the battery-operated wax-pen, why is this? I can control the waxing instead of having too much heat at one spot.

I like to be very careful at times like these. If I had the electric-pen, to much time adjusting every moment too hot, too cold, where to stop on & on!

The battery-heating spot is so small, as against the electric-pen, as it has a very large contact spot!

80) I wanted desperately to make sure that the metal will flow from one side to the other.

82) It looks like a "previous joining" wax was made, but then removed, but why...?

83) This sprue was made oo thin, any remaining wax needs to be cleaned before casting. I could use my battery, pen-tip here!!!

84) Here is one example just why a "connecting sprue" is needed. This wax is so important, any error is not wanted!

85) The 'joining-pink wax' is not attached accurately!...yuk! I'd move the sprue just at the junction of the joinings.

86) This sprue looks attached, but in reality, it isn't!

88) Clean every spot with the greatest of care. Handling this wax with care is so critical, your warm fingers can easily distort this delicate wax form. I would leave the wax in the circles, just to aid in the flow of wax. I can easily remove it AFTER the casting as I need this for easy flowing and not breaking.

91) The "setting-hole" needs to be made clean...everywhere!

92) That gap should not be there, it's quite obvious again, much care needs to be made in wax-soldering. Here again, I'd use my battery-driven, low-heat pen.

92) "I prefer to have extra sprues, instead of just having a few".

95) Just get all of the dirt cleaned, this will cause pin-holes during the metal casting processes.

96) The sprues need to be checked thoroughly and they must be attached all over!

97) Just another view with the same problem, of not being fully joined.

98) This joining looks good, but it really isn't, the wax needs to be well connected!

99) I like to have an easy flow of metal during the metal casting processes.

100)

This wax-coring 3-tooth blade opens up near-solid holes, I use this to make sure the warm or hot wax is getting where it is supposed to be. I would core this 'joining further'.

Many times the melting wax just does a surface melting. Use this rotating blade and allow the wax to "get in there"!!!

101) An oversight, in not having the 2 sprues connecting.

102) Here is the best connecting views. All along the sprue are wax-pen connecting spots!

103) This belt-buckle needs many joining sprues. I am now starting to add additional 2.60 mm rods.

105) Just another view of this "poor- mediocre cleaning" project!

106) Additional wax-joining is always good to have!

107) Front-view of the additional waxing!

108) This is one of a very delicate wax form. I prefer to leave the holes filled in, only for additional support!

108) This very "mediocre cleaning" showing "the before and after", it still needs much cleaning, both in wax and metal!

109) So much cleaning is needed NOW!!! The "Gypsy/Flush Setting" procedures are a long way off. I'm not looking at the filing steps now.

This could have been avoided in the wax stage, but it got completely overlooked, so the price to pay is now...in the cleaning.

110) CLEANING? Where would I start?. I would scrap this wax & start again! This is not the first time that I've done this "scrapping of a wax"

113) These 2.65mm's sprues are not thick enough to allow a good flow of metal to get to all of the spaces need.

I used 3.25 mm's wax sprues.

114) Here is some extra wax, just to make the flowing that much easier.

115) The sprues for these little cuff-links are not joined accurately.

This sprue looks joined, but with your 10 power loupe, you can see that it is not joined really well!

116) This feeder-line is giving the wax additional opportunity of getting more wax to flow.

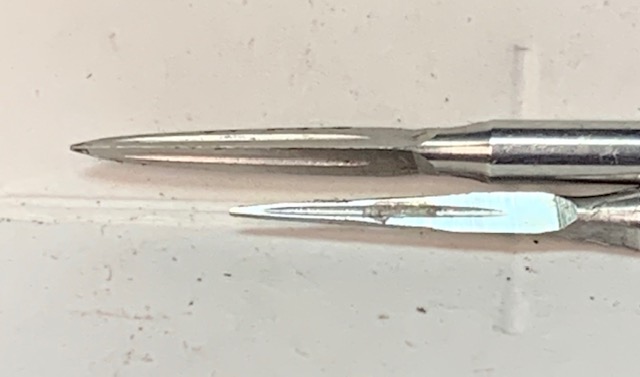

117) These sprues are too thick, in the lower photograph you can see which ones I used instead!

The contacts look good, but in reality, these connecting sprues are too think!!!!

This 2.56mm sprue is too thin allow any wax to feed on other spots on this bracelet! The original sprues were too thick.

118) This is the name of a Wax-File, it has two grits, "Course & Fine". I use both, all the time!

119) This is the "Course grit", it does it's best in "Rough Filing" stages.

120) I could have used cleaning with this "Course & Fine" tooth file, just to make a good attempt in the cleaning steps.

121) I could have used the "Course, half-round file" in the inside of this ring!

123) It would have been easier to add more wax all along this strip!

124) This "cross-over" sprue will make the inside of the ring more secure for casting.

125) Here is the "split-wax, rod technique" that covers most areas of the lower section of the shank.

I used extra wax on the shank, It appeared too thin for my liking!

I decided to wrap the sprue around my bench-pin, just to keep the ring tight and not move around while I'm working on it!

126) Here is an error, no wax was used as one line over-lapped the other...bad mistake!

(BTW, I made this oversight on purpose)..:>)

127) I put this sprue underneath, as I didn't want to destroy any part of the physical shape of the horse!

129) Here is a "Fine-Grit" wax-file, such a great tool, everyone should have and use!

I feel that I should explain to you my well-proven methods, including some of theirs!

After many years of well-proven techniques, I'd like to share my experiences with YOU!

When you apply a wax sprue, there are some necessary techniques. Not everyone will encounter them, but "it's good to know how to work with them, not against them!"

For this essay, I started with 180 photographs, taken over many (3) months, as of now the number is down to 151 Why are there so many? It's because there are times that the wax-creation you just made, will lead to the poor flowing of metal and not reaching the desired areas!

I have just posted 151 photographs, I copied many pictures while posting, my apologies. The number of 151 photographs is still a large number to write about.

About once a week, I've been picking up my waxes from my caster. During my close examination and before the actual casting, I kept finding more "below-average" quality waxes, but these turned out to be just fantastic for this large and extensive blog essay.

About once a week, I've been picking up my waxes from my caster. During my close examination and before the actual casting, I kept finding more "below-average" quality waxes, but these turned out to be just fantastic for this large and extensive blog essay.

I keep saying "OMG, there are mistakes galore here with this mediocre injected wax, but so great for this blog!"

1) In this selection of four waxes, you can see how I made these thin waxes wider and started the process of filing in the holes with my electric, wax-pen! In the background is the battery-driven, mini-pen with only two settings..." on & off "!

3) I used a newer wax, as it had it cast with 'shared claws'. The result was "poor" & not to my liking!

In the lower photo, you can see a better form. There are some mediocre results with its sprues.

4) The joining sprues have a lot to be desired, let's examine them "one at a time"!!

The 'joining spots' are not equally made near the shank & near to the top!

5) The pink top is well made and so is the shank, it's the joining sprue that is my main concern!

6) The wax join needs to remade and the joint needs to be filed then allowing the wax to flow easier!

7) To repeat this process, again the "shared-claws" with its joining that is not well joined..:>(

8) The silver top was a good attempt, but after closer examination, it wasn't good. I scrapped it after casting as too much time & labour were needed in the repairing process.

9) This is a near disaster in the joining of the many sprues. Let's start now to explore each of them.

There are too many side spots during the filling-in of extra wax on the sides. These must be removed.

10) The joining on the left doesn't appear to be well-joined. The ring size must be made NOW!

11) The top appears to be not aligned properly, it looks crooked!

12) The residue of dirt must be removed...NOW!

13) The underneath holes are not cleaned and are not made round. A bad habit to learn!

In my estimation, it looks like a disgusting attempt to create something decent. We all learn from our errors, agree? Again, I did this purposely, just for this essay!

14) The top must be filed smoothly and add new wax to repair any surface defects. The two-axis are not made well, both of them need to be curved. The "length and width" curves were missing!

With my 10 power loupe, I saw some flat surfaces and these were not needed!!

15) I would fill in with more wax underneath to allow for greater freedom of the metal to flow easily.

16) You can see that the top is really crooked. I'd remove the top and restart the 'waxing process'. Being too quick at this stage leads to many errors!

17) As shown in the first photograph, I filled in the holes from wanting to use this plate from a Pave to..? (whatever I need later on). I must use my "wax file" to smooth this wax strip..to be shown later!

18) From this angle, I can see just how poor this 'heating of the sprue' is now looking, This is not acceptable. Not enough wax joining the top to the shank, it's crooked and soldered sideways.

19) Not enough wax in the joining! There is only one solution and that is to remove the top to the shank and start again! It will save you time and save you much labour..:>(

20) This is my diamond-setting bench, before making it into a wax-carving bench. I must have a bur inventory of well over 2,000 burs, many of them are not seen here.

You notice because of my improved eyesight 20/15 <=> 20/20, I don't need the use of a microscope.

(20-B) This is my same diamond-setting bench, with much modification, it's now a waxing bench.

21) In this average-looking, rubber mould is a regular ring that will soon be used for casting. There is a definite problem lurking!

23) Don't pull out the warm injected wax. It's warm because of the wax has to be warm so the wax will flow into the cavity of the rubber mould!

24) THIS IS THE PROBLEM. You see two thicknesses of the sprue. I will never accept this for any form of casting. Plus the two sprues are of two separate thicknesses. Totally not acceptable..!!!

25) Good grief! This section must now be removed and re-attached with even sprues.

26) You can see just how the error was made after the two metal sprues were attached before the metal mould.

27) In this different project, I added more sprues everywhere. These were added for wax and then even metal flowing for the casting of the metal.

29) Now you can see how clean the mould looks, no errors anywhere!

30) I'm now joining the "inside, cross-over piece of wax", only for easier flowing of wax in the mould. There are so many steps to watch out for, in this topic.

If one error is not seen, you might have a very poor result, there will be many 'ripple effects' leading further to poor castings. "THERE ARE NO SHORT-CUTS".

I want, if needed, extra sprues just to make darn sure the wax or metal flows where it is required.

32) These "light-coloured spots" are the filed areas where the additional waxing took place.

33) You will see just where I place my middle finger. I place the wax just here and only for support.

The finger is warm and this soft heat might soften the wax, plus I want full access to any wax working. If I place my wax on my bench pin, I won't have full or complete access.

This is such a delicate process, it can be a bit frustrating, to say the least.

34) To avoid any warm-finger bending, I hold my fingers always on the sprues. Here, I am attempting to fill in the setting holes, this is of no consequence to this topic, but just to show you how I'm now

holding this very fragile wax pattern.

35) Sometimes I feel that there is a need to set more stones into my (favourite) heart pendant. That being the case, I will add more or remove a few holes, I can't do this in metal.

The best way is to do this in wax, it's cheaper and must faster...:>)

36) Here is a little collection of sprues & additional 'feeder lines' for better flowing of wax!

37) This sprue looks good, but in truth, this is a very mediocre joining of sprues. They are not fully joining, or attached.:>(

38) All of my rubber moulds had this extra piece of wax, I didn't realize this until a few castings later.

Always check & re-check your mould, in case of a constant error taking place. As like this, locate the error in your rubber mould and either discard the mould or fix it, if you have the opportunity.

39) I always like to add more sprues, I don't care if I have to cut them off afterwards, at least the metal is flowing better, because of them. This step is so-o important.

40) I'm so happy with this correctly made design. Since this design is small, I didn't need anything further. If the sprue is longer, the hot wax will cool too fast & not reach the tip of this horses head.

41) This wax-form is full of extra residue, it needs to be removed NOW! This is so much easier than in the metal stage.

42) Clean out the setting holes, plus clean out the extra straight lines seen underneath the horses face! Basically, clean everywhere, including "the eyes" of the horse.

I mentioned so many times before, it's far easier to clean now, than after!

3-teeth and come in only two sizes. Please be careful, as they are extremely sharp & cut the skin with little effort!

46) Please excuse the "out of sequence" photographs!

Clean the inside of the wax-circle, try and remove all of those 'dirt spots'.

The easiest way is to use your bur, and dig deep and then fill in the hole again. Your wax for the metal casting must always be in pristine condition.

47) Here is a close-up of those dirt spots, these must be removed. While you're at it, add more wax to the sprues.

48) I would remove these ill-placed sprues and attach them again.correctly and in the middle of the project.

49) This is the reason just why the sprues must be centred correctly.

50) I'm not at all satisfied with just one or two sprues. For this important project, I need full access for all of the metal to flow to all areas of the circle.

51)

52) Now you can see just why extra sprues are needed. "Always have extra, more the merrier!"

53) In this photograph, I just 'flooded' the under-neath 'demo-plate' with extra wax, "I'd rather be safe, than sorry!"

54) I separated all of the claws before casting. If some of the wax-claws are missing, then add wax to the tips...NOW!

55) The 'Pink' added line is added just in case an insufficient amount of metal gets to reach the very important areas.

56) On this wax for "three horses", I added three additional wax-lines, I'll 'feel' safer that way during the casting.

57) I found a better wax-sprue, with a wider base, can you see the difference? Agree?

58) You can see the hot wax at the tip of the wax-pen. Drop it to the base of the sprue, not at it.

59) Here is where the hot wax should be situated. If the pen-tip touches the sprue, heat will destroy the wax, you need it just at this one spot!.

60) This is how much extra wax you need, the sprue is slightly crooked, don't worry about it. We're only concerned with how much will be given to the shank.

The shank looks a bit short of wax, I would add extra along from the middle and further along the shank. It looks too thin on the 'left side'..:>(

61) Here is a great idea for you in applying a new wax sprue. Just split the end with your saw-blade and split it down until you can easily bend the wax. Then touch some wax to the end until it will hold the wax item.

62) Get that new wax area right into your item, as seen! Let the warmth of your fingers mould the split-ends just to hold it.

63) Now you can just flood the whole area with wax!

64) Now you can compare my "additional-waxing" to the original. Which do YOU approve?

65) I always add more wax to the base and the main-line.

66) Here is another example of 'additional waxing'.

67) This is another example of putting more wax-lines to very long & thicker projects. I would have used even more near the front of the horses face!

69) The PINK coloured wax is the newer wax that was placed to reinforce the original sprues. As I only have one chance in this casting, I don't want it to be messed up!

70) Always look with a 10 power loupe, as sometimes a sprue may not be solid, as shown here!

71) On a belt-buckle, make sure that the "belt-pin" doesn't touch any of the additional wax-joins!

71) These little 'marked spots' are original injection spots, fill them in NOW! When everything is completed, double & even triple check for any little defects.

This is a very difficult casting, I won't allow for any unforeseen problems, even though this is two-piece casting. Problems might occur!

I want everything clean, it's much easier to 'fix' the problems in the wax, than in the metal.

I suppose I'm too precise, but in this 'game', being precise is the 'route to take'!

72) Although this supplying of sprues were attached by another company, I always check them once they get into my hands. Those folks think of "speed & money, not always wanting to be accurate"..:>(

73) When you are attaching additional settings, please make sure your waxing doesn't get too sloppy!

74) There seems to be a "VEE" shape in this sprue, not always is this a good omen. Get more wax in between the "VEE" and be safer!

75) "Not always the joining of sprues should be in the horizontal stage" Ignore this and just use your imagination and place your sprue anywhere you want.

Just get that sprue to join anywhere that it is comfortable! In this photograph, I used height to 'jump over' and get to the right spot!

76) My main concern is to have the wax & metal flow from point "A" to point "B" successfully! I decided to change the number of sprues.

77) As this is a very important casting, I don't want any errors of any kind to occur anywhere!

I don't care how the sprues look, my main concern is "will the metal flow where I want it to flow?"

If I didn't have the "green" sprue, there would have been a problem of metal to flow in the circle!

78) This is one of a very delicate casting that I've seen, or used in a long time. Look at the little joining of the waxes, the actual joining is poor!

Look at photo #81 and see how this looks from a distance. I had to avoid using this wax joint, as before someone else did this originally.

NEVER USE SOMEONE ELSE'S DECISIONS. Use yours, 100% of the time.

Moral of this; It's your creation & you should make your own decisions where the sprues must be.

I like to be very careful at times like these. If I had the electric-pen, to much time adjusting every moment too hot, too cold, where to stop on & on!

The battery-heating spot is so small, as against the electric-pen, as it has a very large contact spot!

81) I'm using 3.25mm wax sprues, the reason is that I need to have a wider flow to reach all of the important spots!

82) It looks like a "previous joining" wax was made, but then removed, but why...?

83) This sprue was made oo thin, any remaining wax needs to be cleaned before casting. I could use my battery, pen-tip here!!!

84) Here is one example just why a "connecting sprue" is needed. This wax is so important, any error is not wanted!

85) The 'joining-pink wax' is not attached accurately!...yuk! I'd move the sprue just at the junction of the joinings.

87) For a design like this, being so very thin is and having a very thin wax form. Please attach every sprue of 2.65mm with much care! Our aim is to remove all of the errors before they happen.

88) Clean every spot with the greatest of care. Handling this wax with care is so critical, your warm fingers can easily distort this delicate wax form. I would leave the wax in the circles, just to aid in the flow of wax. I can easily remove it AFTER the casting as I need this for easy flowing and not breaking.

89) That line see above, is a wax-carving "saw blade". I used a very thick sprue. I want as much of the wax to flow uniformly.

The twisted saw blade IS THE WAX-CUTTING BLADE.

90) This wax-ring needs much cleaning, it's quite obvious how much it needs just to be made ready for casting. It's (50%) border-line being acceptable

91) The "setting-hole" needs to be made clean...everywhere!

92) That gap should not be there, it's quite obvious again, much care needs to be made in wax-soldering. Here again, I'd use my battery-driven, low-heat pen.

92) "I prefer to have extra sprues, instead of just having a few".

93) On this "4-Leafed, Clover", there are only a few little sprues that are needed!

94) From the front, the sprues are not being seen!

95) Just get all of the dirt cleaned, this will cause pin-holes during the metal casting processes.

96) The sprues need to be checked thoroughly and they must be attached all over!

97) Just another view with the same problem, of not being fully joined.

98) This joining looks good, but it really isn't, the wax needs to be well connected!

99) I like to have an easy flow of metal during the metal casting processes.

100)

This wax-coring 3-tooth blade opens up near-solid holes, I use this to make sure the warm or hot wax is getting where it is supposed to be. I would core this 'joining further'.

Many times the melting wax just does a surface melting. Use this rotating blade and allow the wax to "get in there"!!!

102) Here is the best connecting views. All along the sprue are wax-pen connecting spots!

103) This belt-buckle needs many joining sprues. I am now starting to add additional 2.60 mm rods.

104) This is the epitome of "poor cleaning", so much needs to be done before any casting!

105) Just another view of this "poor- mediocre cleaning" project!

106) Additional wax-joining is always good to have!

107) Front-view of the additional waxing!

108) This is one of a very delicate wax form. I prefer to leave the holes filled in, only for additional support!

108) This very "mediocre cleaning" showing "the before and after", it still needs much cleaning, both in wax and metal!

109) So much cleaning is needed NOW!!! The "Gypsy/Flush Setting" procedures are a long way off. I'm not looking at the filing steps now.

This could have been avoided in the wax stage, but it got completely overlooked, so the price to pay is now...in the cleaning.

110) CLEANING? Where would I start?. I would scrap this wax & start again! This is not the first time that I've done this "scrapping of a wax"

111) Here is a collection of a series of "brass rings" I purposely & poorly attached to a 'Wax-Tree".

My caster asked me "why did I make such a poor casting? I told him "that I did this to show my students what happens if no thought is being given in making a quick tree in wax".

Then he gladly made the casting for me and fully understood my purpose. I've been showing these two 'trees' for over 12 years and now it's going to be put into my blog.

112) The metal setting area is very limited, especially in its width. Much more wax is needed...everywhere!

113) These 2.65mm's sprues are not thick enough to allow a good flow of metal to get to all of the spaces need.

I used 3.25 mm's wax sprues.

115) The sprues for these little cuff-links are not joined accurately.

116) This feeder-line is giving the wax additional opportunity of getting more wax to flow.

117) These sprues are too thick, in the lower photograph you can see which ones I used instead!

The contacts look good, but in reality, these connecting sprues are too think!!!!

This 2.56mm sprue is too thin allow any wax to feed on other spots on this bracelet! The original sprues were too thick.

118) This is the name of a Wax-File, it has two grits, "Course & Fine". I use both, all the time!

119) This is the "Course grit", it does it's best in "Rough Filing" stages.

120) I could have used cleaning with this "Course & Fine" tooth file, just to make a good attempt in the cleaning steps.

121) I could have used the "Course, half-round file" in the inside of this ring!

122) This "Fine-File" could have nicely cleaned the sides of this strip of this wax-frame. But first, I saw that some wax was missing. I added a fair amount of fresh wax to fill in the gaps on the side.

123) It would have been easier to add more wax all along this strip!

124) This "cross-over" sprue will make the inside of the ring more secure for casting.

I used extra wax on the shank, It appeared too thin for my liking!

I decided to wrap the sprue around my bench-pin, just to keep the ring tight and not move around while I'm working on it!

(BTW, I made this oversight on purpose)..:>)

128) Here is an additional sprue to give more flow of metal after casting!

129) Here is a "Fine-Grit" wax-file, such a great tool, everyone should have and use!

130) In this last photograph, is of a bow-tie using a (Pink) 3.25mm's wax-rod, showing how and where the one sprue is joining. I used more waxes to help the flow of wax-to-metal to get into every spot that it's needed.

In conclusion, with all of these photographs spanning nearly 3 months of writing and taking nearly 160 photographs. I sincerely hope that you have learned that attaching wax sprues is very difficult. I rate this on my "Difficulty Scale, of 8 out of 10!"