The underside of this enormous pendant is a Diamond Setters dream, why is this? Every bit of my training went into making this gold pendant into a "Piece of Usable Art".

=====================================

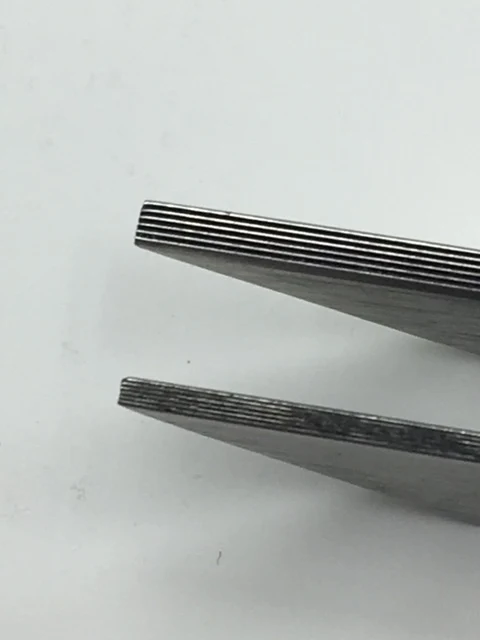

Rule number one is to countersink every hole from the underneath. This will give a uniform shape to all of the drilled holes, thus leading to a cleaner and smoother surface.

The Rate of Difficulty was an unbelievable "50, out of 10".

(This pendant wasn't polished as to my clients wishes, all I did was the stone setting).

Here is the 'finished' medallion prior to being shipped back to the client.

I held on to this medallion for a short while just in case of further changes.

Since I had very little areas to Bright-Cut in the recessed areas. I then decided to just fill in the spaces with a multitude of Beads.

With this pendant sitting in my fingers you can see the relationship to it's overall size.

At the curved spots on the disk I used two sizes of diamonds. The pre-drilled holes display where these two sizes of stones will be used or set.

As all of these stones are diamonds, I placed the largest diamonds where they would be seen at first glance.

The main body of the Dolphin was full of gentle curves and elevations, at this point I held the Dolphin in my leather gripping ring clamp.

At the near completion of this intense project, the outer stone setting can be seen.

What changes were to be used in the tail of this Dolphin? First of all my client wanted smaller diamonds (even after the stone setting) the holes had to be filled in. Then he wanted even MORE diamonds from 7, to 10 stones all of different sizes. OUCH!

Oh by the way, the 'client' now wanted white diamonds in the head of the Dolphin, where there weren't any before. So many changes, as these changes occurred literally every few days.

I planned every placement of diamonds even before a hole was drilled for any of them.

When a line of stones was decided upon, I used a felt-tip marker to 'plot each stone'.

If I broke my 'twist drill' from the over-heated bur in the drilling I would have a major repair being started.

You can see some of the faint 'stone plotting recesses' at some of the desired spots.

This photograph shows the exact method that I used in marking the spots prior to drilling. You can see the felt-marker plotting and then a recessed spot prior to drilling.

Just for some extra colours for my' stone plotting', I used a few ink coloured pens.

Even the size of the round bur for 'counter-sinking' of the holes had to be carefully worked and decided.

This drilling, repairing, plotting of stones along with setting, took me nearly 4 WEEKS.

The intense strain on my eyes had to be dealt with continually.

The intense planning added many more days & hours to this project.

If one diamond was out of alignment by just 1-2 mm's. I removed a complete section and re-arranged many stones...again. Time was never wasted, planning was so very critical.

This 'stone plotting' was like using a GPS on the gold plate. Every diamond had to planned as to where it will be set, not to mention the stone size because of the location..

There was to be not one space left open without a diamond, or 'decoration' beads. Many sections of the anatomy of the Dolphin had to decided where each stone was to be set.

You can see the different sizes of diamonds that were to be used.

"

Counter sinking" of the holes was a major task prior to the stone setting. All of the bur drilling had to be of the same size. "Uniformity" was the key element in the drilling.

You now see just how wide the flame was to allow the solder to 'flow'.

After plotting the white 'helmet' diamonds, I again of course, counter-sunk the new drilled holes. There was so much labour that went on 'behind the scenes'.

After the stone setting was completed, the client wanted more white diamonds on the helmet and around the letter "M." You can see the variety of sizes.

BTW, not one diamond was misplaced during this 'mind numbing' experience.

If I needed to drill a few more holes, then I did so...BUT still knowing that the 'drilling of EACH hole had to be afterwards to get be 'Counter-Sunk'.

This was an ultimate diamond setting project of my career. Of course, there were no short-cuts even thought of.

My client and I decided how many extra diamonds were to be added then he shipped them to me. We exchanged photos during this long diamond setting process, if he decided more stones should be used, then we agreed and decided where each new stone should placed.

It is easier now to see the many angles and elevations around the body of the Dolphin.

If a diamond was placed in a wrong spot, my jeweller greatly assisted me in his soldering. His torch-flame had to be at a higher temperature than 'normal' thus in him using a wider overall flame.

The pendant was of a very thick design and he was very concerned that no diamonds got 'burned' from the higher than normal temperatures.

If just one stone had to be relocated, or moved (back to my jeweller it went). The metal was so darned thick that his intense flame was the only solution we had.

Just to fill in the metal for one hole was a challenge, as he was very concerned of over-heating the metal with the diamonds.

Many times during the diamond setting and partial setting of the Pink stones, he would email me more stones to set. I HAD TO COMPLY TO HIS (THEIR) WISHES.

This 2-week (originally planned) process took me almost 4 weeks in total. The time that was spent was due to the ongoing changes in planning and cross-country shipping.

For legal reasons, I can't divulge the exact name of this disk, the final destination had to be kept secret. I never even asked how much the true value of this item was.