"Bezel Setting, Diagrams! (4th in a series, of 8 diagrams!)

To not include a "Bezel Setting" in this series, is a total mistake & an oversight!

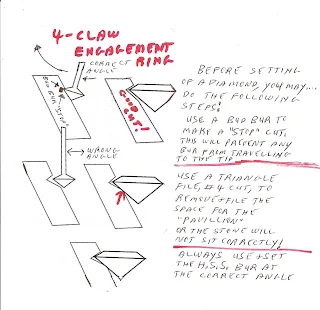

"Bright-Cutting" is so very important and essential in achieving perfection, a very clean & highly polished graver surface is essential in Gemstone setting!

The hammer-face is critical as well in hammering metal around the stone, it must be perfectly flat, clean & with no telltale marks anywhere on the face while hammering. I won't use a light-weight hammer-head & together with the handle.

The appropriate "Complete, Hammer-Weight" should be (no less) than 85.0 grams. The 'hammer-face' should have a weight of 11.75 grams and size of square 68.50 mm's.

The Bezel frame MUST be sitting against the stone...'all around'..with no spaces of any kind between the Stone Facets & the metal! Why is this so important?

While you are attempting to "Bright-Cut", the curvature of "Cutting" must be uniform in its application at all costs!!!

It will now appear to be needing of re-hammering if there are any spaces, (as shown in the first diagram)!

In the second diagram, the "Hammer-hitting" must be done in two separate stages. The first is to gently move the Bezel- frame or wall much closer to the oval-stone, kindly tell me how this is done? Your light-weight hammer will move the "Bezel-Frame" as shown, in number #2!

Once that is done, then you can now with 'great care' hammer the bezel over the facets. NEVER HIT DOWN onto the stone. But always hitting at an angle of 45 degrees and always with a more stronger downward force.

If you hit 'downward strokes', your chances of "damaging the table-facets" are excellent!

The 'hitting sequence' is important as this routine, as it will not allow the 'stone to drift, or rotate' while you are trying to secure the movement of the loose stone!

What you are really trying is to prevent any sideways or twisting motion. This action "is like using a pair of pliers" as its holding the stone in its place!

I would (constantly use) a 10x loupe & examine for any 'open spaces' under the Bezel, to the stone. If there are any, repeat the hitting action until the Bezel is down & secure to the stone. While "Bright-Cutting", these 'open spaces' will look not look appealing & of course, just darned ugly!

To not include a "Bezel Setting" in this series, is a total mistake & an oversight!

One aspect of this setting is to understand that 10-15% of the stone will be covered by a metal-rim! I won't let that bother me, is that I will "Bright-Cut" all around the 'inner-bezel' frame. As you see that although much metal is covering all the Facets, just above the 'Girdle' of the stone.

"Bright-Cutting" is so very important and essential in achieving perfection, a very clean & highly polished graver surface is essential in Gemstone setting!

The hammer-face is critical as well in hammering metal around the stone, it must be perfectly flat, clean & with no telltale marks anywhere on the face while hammering. I won't use a light-weight hammer-head & together with the handle.

The appropriate "Complete, Hammer-Weight" should be (no less) than 85.0 grams. The 'hammer-face' should have a weight of 11.75 grams and size of square 68.50 mm's.

The Bezel frame MUST be sitting against the stone...'all around'..with no spaces of any kind between the Stone Facets & the metal! Why is this so important?

While you are attempting to "Bright-Cut", the curvature of "Cutting" must be uniform in its application at all costs!!!

It will now appear to be needing of re-hammering if there are any spaces, (as shown in the first diagram)!

In the second diagram, the "Hammer-hitting" must be done in two separate stages. The first is to gently move the Bezel- frame or wall much closer to the oval-stone, kindly tell me how this is done? Your light-weight hammer will move the "Bezel-Frame" as shown, in number #2!

Once that is done, then you can now with 'great care' hammer the bezel over the facets. NEVER HIT DOWN onto the stone. But always hitting at an angle of 45 degrees and always with a more stronger downward force.

If you hit 'downward strokes', your chances of "damaging the table-facets" are excellent!

The 'hitting sequence' is important as this routine, as it will not allow the 'stone to drift, or rotate' while you are trying to secure the movement of the loose stone!

What you are really trying is to prevent any sideways or twisting motion. This action "is like using a pair of pliers" as its holding the stone in its place!

I would (constantly use) a 10x loupe & examine for any 'open spaces' under the Bezel, to the stone. If there are any, repeat the hitting action until the Bezel is down & secure to the stone. While "Bright-Cutting", these 'open spaces' will look not look appealing & of course, just darned ugly!

Contact me at "gerrylewy18@gmail.com" 24/7!