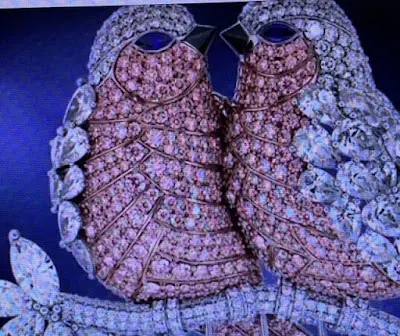

This photo is the reason why I'm explaining Bezel Settings. This is the ultimate in Bezel work, as there is no other way of showing you the techniques than in text & photos.

Videos are nice but rather difficult to produce. Text is better as there is no chance of getting a full blown photo in a video. No speaking, no chances of missing an important fact in gemstone setting.

The Oval and Round Bezel settings are basically the same, except for the shape of the stone.

When you dealing with large stones, the Culets of the stones might protrude through bottom while being hammer tightened. Then this the reason why the Culet must never touch the steel mandrel, then the point of the stone won't get damaged.

IT CAN (easily) HAPPEN.

Here is a photo of a broken culet, say "goodbye to the stone".

On an Oval Bezel, you can see the folded 'bezel frame'. The bezel setting wall has been cleaned with a Pumice Wheel #180 grit, finally a #1,000 Pink coloured pumice wheel.

If you choose to use a cloth wheel, then all of the sharp corners will be 'rounded' during the important polishing processes. (I wouldn't use this technique).

This ring bezel is aptly named "Half-Bezel" as parts of the frame is being reduced. There is more of the stone being exposed and more light will get into the stone.

On any Bezel setting that has come from the casting department, there are extra pieces of metal that need to be removed, NOW. After the setting has been done, then it's too late. Have this ring thoroughly cleaned aka 'Pre-Polishing', NOW.

After the setting has been completed then the 'Bright-Cutting' must be done also NOW.

Here are two High Speed Steel burs aka HSS burs. The bur on the right is good for bezel setting, the bur on the left shouldn't be used. As the teeth are badly worn down.

The size of the bur should be no larger with the combined 80% of the stone 'width and length'.

This bur is too large to use, why? There won't be any allowable movement within the bezel setting. If the width is 6.0 mm's, then the width of the bur must not exceed 4.75 mm's.

In this 'before & after' viewing, there has been some very interesting techniques being explained. I sincerely wish that you have learned some newer aspects of Bezel Setting.

.jpg)