This might seem like an easy process, but it's full of unforeseen problems. This essay might be somewhat convoluted, as 'we' are now dealing with many various shapes & sizes.

============================

1) One of the problems is incorrectly placing the new wax on the 'tree' before casting. There shouldn't be waxes sticking away from the main 'tree' as seen in the brass display.

2) Where must the sprues be attached to each item?

3) Weigh the total waxes to estimate the amount of metal you need for casting. This weight includes the metal for the 'tree' as well.

4) The wax just for the 'tree' is also very important. Why is this? The tree must weigh enough to be able to hold the items for casting. This metal can always be used again & again.

5) Weigh each wax, including the 'tree'. Don't just guess; you must be 100% accurate.

6) If you have an 'extra large' new item to cast. Keep them separate from the smaller items in the flask. If needed, use a larger flask.

7) Keep the waxes close to the 'tree', but NOT TOUCHING other waxes.

8) Always allow space between any two items; this is to allow the metal to flow freely during the casting process.

The hot metal could very easily pierce the 'hollow cavity in the investment' while being in the centrifugal process.

This is the maximum thickness of the 'tree'; if it were any thicker, there would be too much metal to accommodate in the weighing process.

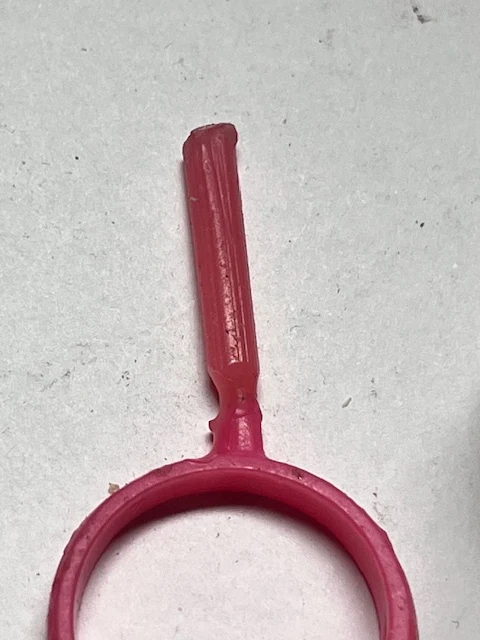

You will notice the thickness of the sprue that was initially created for the wax ring. My own sprue is about the same thickness, interesting to find the same. Always put the heat on a low temperature as you need to gradually heat/warm the joining, NOT MELTING THEM BOTH. This sprue is too long and must be shortened. Why now? Not when the hot metal is flowing, THE CASTING HEAT MUST BE KEPT AT 1,600 (Fahrenheit)

TEMPERATURE & AT A CONSTANT RATE. When the metal is reaching the claw settings further up into the ring, the metal starts to cool down, hence there could be 'missing claws'.

If you want to do a minor 'repair' on some of the shortened claws..DO IT NOW! With the reduced length of the 'tree', the hot metal won't cool down so fast. The sprues on the main shaft and ring are not of the same width. Use your wax pen to increase the widths to be the same.

Make sure that there are no extra 'remnants of wax' still remaining on the model before the metal casting. It is advisable to create a wax sprue to the inside of the wax, instead of the outside. This is to reduce any major metal filing during the cleaning.

When you finally attach the wax sprue, make sure that the connection is adequately made, thick enough for the flow of metal.

Always keep the wax sprue sufficiently attached with added wax. We want the metal to flow with no problems.

When the wax is being joined, I MELT THE WAX ON BOTH SIDES OF THE SPRUE. This will give a good source of metal being given to the new item.

Don't allow the new waxes to 'fan out'; if you do, then you will need a wider flask.

The new sprue MUST BE THE EXACT SAME WIDTH AS THE ORIGINAL SPRUE.

The problem here is that the inner wax shaft is too long. What you are dealing with is unwanted extra metal. REMOVE THE HEIGHT IMMEDIATELY!

The next problem is quite obvious, how is that? The horse's head is too close to the wax shaft; all alterations & corrections MUST BE MADE NOW. You will notice that one of the new waxes was made to be formed at the tip of the pole. I corrected the spacing of the horse's head to be further apart.

A long wax sprue does nothing to help with the flow of metal. Actually, the long sprue allows the hot metal to cool faster and we don't want this to ever happen. This is a repeated picture of a long sprue; shorten it before doing any more assembly.

Compare these three 'trees'; the wax stem has a 'closer-fitting' spread. The brass clusters have their rings at double the overall width. REMEMBER that the widespread use of the 'wax collection' makes you choose a larger flask. Not always is this the best choice.

Here is a great question. Which 'layout' would you choose?

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

No comments:

Post a Comment