==============================================

This oil-stone is the best "Fine-grit, India Oilstone, FB6" to buy and it lasts for literally years.

This oil-stone is the best "Fine-grit, India Oilstone, FB6" to buy and it lasts for literally years.

All of my specially needed 156C burs are kept in their own wooden box.

This "3-in-1" oil has a very thick viscosity, that means it just never evaporates. It lubricates just great! I have a fine range of brushes of different bristle thicknesses. I use a paint brush or even a tooth-brush.

I'm using a #180 grit, "Tapered, Pumice Wheel" instead of a Triangular file.

I use a drafting pencil to fill in the pores of the Polishing Paper. This process will change the paper-grit to a much finer texture. This result will be from a #800 to now a #1,000. Your #1,000 grit paper will become #1,200 or even a #1,400.

I could use the drafting pencil on any paper that is needed.

This Hand-Vise is a 'best friend' at my bench, it prevents me from using any "Flake-Shellac". This shellac can be so difficult to clean.

In this photo, I Gypsy-Flush set multiple stones in one ring.

From one single opening I set multiple stones. I bead-set the inner opening, just for security.

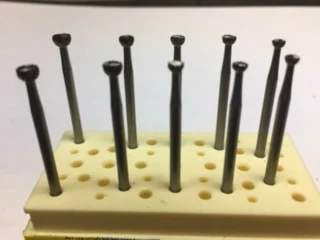

Here is the full set of "Cup-Burs" commonly named "77B". Yes, I have at times actually used the larger size.

Here is the same set beside the ROUND bur assortment.

Here I am using a "High-Speed-Steel" aka HSS bur that is great for Bezel Setting. NO I will not use the 156C, why? The teeth are further apart and grind away much of the un-needed metal where the 156C bur only glides along the metal. But not digging into the metal.

In this HSS bur assortment, are of the smaller size. I'd use them only on the smaller claws/prongs.

This clamp is a real help in again the use and avoiding "Shellac".

Another reason why I prefer the "Mini-Vise" is shown here. The 4 little mini-posts on the sides will grab the item very tightly, but not digging into the item.

I use a magnet many times just to remove any residual amounts of metal from the constant use of the graver.

To easily remove the little shards of steel, I will use "lighter fluid" to keep the metal in suspension and then the magnet will lift the steel off of the oilstone.

Here is a good example of "Paper Polishing" the graver.

This is the commonly used Flake Shellac, it's not too often now would I use this method. The only way I could remove the shellac is to immerse the item into "Methylated Alcohol". After 1/2 hour, then the shellac will be removed.

Here is a close-up of the #77B bur.

I put this bur to a test in grinding away the outside rim, why? I want the edge of the teeth to get close to the claw/prong, how is this done? It's very easy, just put your bur inside of the hand-piece and rotate the bur on your oilstone and then the teeth will get right to the edge of the claw.

Here you can see the HSS bur starting to cut a bearing into the claw/prong. After this cutting, I'd use my Cup-Bur aka (77B). There is no need to use a file to make any claw round with a triangular file.

The top two handpieces are antiques for gemstone setting, why? With the lower instrument, it gives me complete control over holding the bur while setting diamonds. There is not heavy flex-shaft to tire out the setters hand or even the arm.

With the need to remove any shellac off the item, no Bunsen burner is needed. All I do now is to use the portable torch, as shown here.

This hand-held "Tube Holder" is a great thing to have at your bench. It has numerous sizes for all sizes of tubes. this is a must for your bench.

Here is another photograph that was shown above. I always have duplicate polishing sticks, just in case one gets damaged.

Here I am rubbing my graver ONLY on the Drafting Pencil area on the paper.

I drilled out a receptacle in my bench pin, I use it ONLY FOR MY LOOSE GEMSTONES.

This attachment is a lifesaver, it's named "Inside, Ring Holder". It also has 10 assorted ring sizes to work with, the one I use is 25 years old. In the background is a thumb-guard, it prevents any damage to my skin of my thumb.

When examining a large diamond, keep your fingers off of it. Use a 3, or a 4 prong stone holder.

The correct & registered name is shown on the side "Setters Hold It" Another reason not to use shellac.

I use only #4/0 size saw blades, jewellers might use #3/2, or a #2/0. But for Diamond Setting, the width of the blade is ample for what I need for it.

Here is a full range of HSS burs, ranging from 2.25mm all the way up to 9.75mm's.

"Bush" burs are the manufacturer of these great 77B burs.

This wax holding hand-made devise is a "life-saver". It is a combination of (warmed up) crushed-charcoal mixed with candle-wax. I have different sizes for a multitude of stone widths.

My specially-ordered graver handles come with 2 screws as this is then holding the graver securely 100% of the time.

I can use any length of graver and place any one of these gravers being shown into their handle.

This is my favourite hammer, these are not cheap. The name is a "Bedaco, Reciprocating Hammer" and it can be used on any flex-shaft motor cable..

The name "Foredom" speaks for itself.

Here are a large assortment of "156C", "C" means Carbide. "Undercutting Burs" also named as 'Bearing Cutters".

Here are two shapes of files that are used ONLY in gemstone setting. Pillar file of #2 grit and Triangular #4 cut. I scribe with an ink-marker to help me find the cut of the file, that I need.

Here are my full range of metal claw/prong pushers. They come in Brass & Steel, not too mention different shapes for different purposes.

From an old bottle cap, I cemented it to my bench top and use it only as a receptacle for my "3 in 1" oil.

The two implements are my "Side-Cutting" pliers. I use these to cut my claw/prongs shorter.

Here are my vast array of pliers, at one time or another these have been used during my 60 years of setting gemstones.

I have these loupes all with specialized lens widths, each of them are with 10 power strengths.

This Pink Pumice Wheel is of #1,000 grit, these wheels come with a Flat and Tapered configuration.

The Emery wheel is named "Snap-On, Emery" of a "Medium Grit".

This Pumice wheel also comes in a#180 grit both in Flat & Tapered shape.

All of my "Twist-Drills" are kept separate from getting lost, they stay in a wooden box.

Hoping that you learned what setting tools are being used at a moments notice.

Read, Learn and have fun! My email is "gerrylewy18@gmail.com".

No comments:

Post a Comment